Machines of the thermal cutting "RADIAN"

RADIAN thermal cutting machines

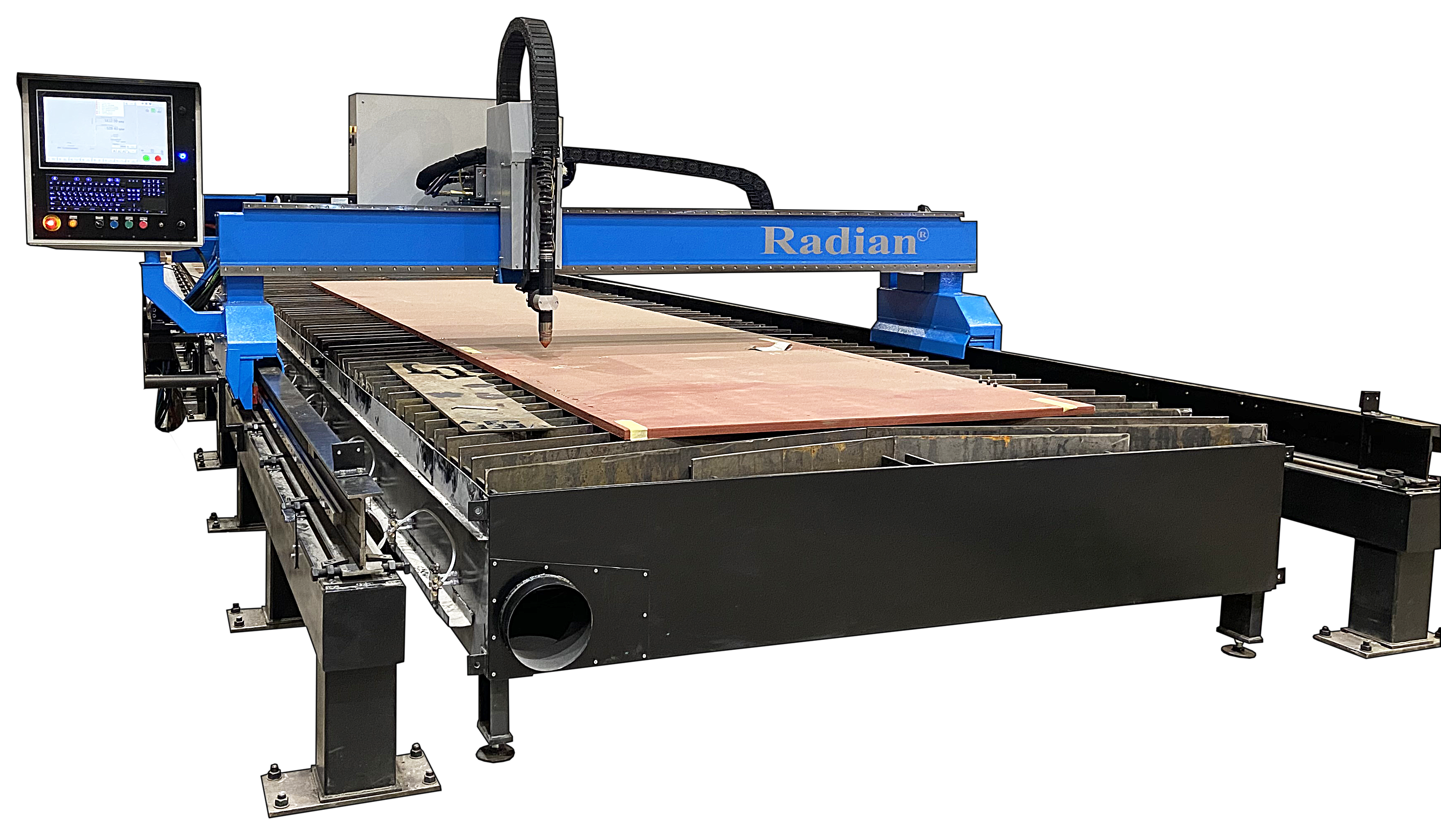

Radian® CNC thermal cutting machines produce high-precision plasma and gas cutting of low-carbon, alloy, including stainless steels and alloys, colored metals and alloys in a wide range tovshchin.

The possibility of machine configuration depending on the size of the peeled sheet, the choice of plasma and gas-oxygen cutting systems and their combinations, the type of cutting table allows you to produce a complex that is completely similar є To your bosses.

This class of machines best matches all the benefits and realities of chicken production.

Providing high-precision cutting of metal coupled with reliability and ease of maintenance, the machines will serve many years in your production.

Radian® CNC thermal cutting machines produce high-precision plasma and gas cutting of low-carbon, alloy, including stainless steels and alloys, colored metals and alloys in a wide range tovshchin.</ span>

Gantry thermal cutting machines of the Radian®-2000, Radian®-2500 and Radian®-3200 series

Possibility of machine configuration depending on the size of the cut sheet, choice of plasma and gas-oxygen cutting systems and their combinations, type of cutting table let you identify a complex that completely corresponds to your tasks.

Possibility of machine configuration depending on the size of the cut sheet, choice of plasma and gas-oxygen cutting systems and their combinations, type of cutting table let you identify a complex that completely corresponds to your tasks.

This class of machines best matches all the benefits and realities of chicken production.

Providing high-precision cutting of metal coupled with reliability and ease of maintenance, the machines will serve many years in your production.

Radian® portal thermal cutting machines are used in industrial enterprises and there is a large number of production plants for high-precision shaped cutting of metal – cutting plasma and gas-oxidizing, as well as These methods can also be used.

Depending on the rolled metal that you are using, we recommend that you choose the standard size of the working area:

- width, mm: 2000; 2500; 3200

- double: from 3000 to 24,000 mm

- for the needs of a non-standard work field, it is possible to prepare it on an individual basis.

It is important for metal that is formed, solidified by plasma or gas-oxidation type cutting, or their combinations:

- • Plasma cutting low-carbon, alloy steels (structural, special and others), aluminum, copper, etc. Plasma marking and marking of blanks is also possible. This method is effective in a range of thicknesses from 0.5 to 50mm. Radian® thermal cutting machines can be equipped with any Hypertherm® (USA) plasma cutting system that best suits your needs, including the new XPR systems. >.

- • Gas cutting cutting including low-alloy alloys. The principle of the foundations in the process of the mountainous penetration into the sour, which surrounds it with the active area of the vikoristan. The Radian® tarnish cutting machine is equipped with high-acidity gas cutters manufactured by Messer and cuts sheets up to 300 mm with excellent results.

For optimal performance of the gas oxygen supplied by you

For optimal performance of the gas oxygen supplied by you

These plasma machines are equipped individually in configuration

from 1 to 5 carriages:

- autonomous robot with one support

- synchronously shaped carving with carriages for increased productivity

- simultaneous straight cutting of a number of fingers with fingertips instantly to prevent thermal injuries when cutting dark skin

Car support.

The caliper body is cut on a coordinate-boring bench.

The caliper body is cut on a coordinate-boring bench.

The efficiency of the assembly is ensured by high precision manufacturing and the absence of regulatory assemblies (except for the installation brackets for Omron end-caps).

Trim the cutter equipped with a magnetic device to protect against damage to the cutter when it is closed.

The mechanics of the supports are implemented using a kinematic scheme on linear guides and carriages “Hiwin”.

This solution requires minimal maintenance (cleaning and oiling), ensures high precision of movement and maintains its technical characteristics throughout the entire term of operation Verstat.

Portal beam

Portal beam

The design of the portal beam with increased rigidity ensures increased accuracy and dynamics of the machine’s operation due to the installation of linear guides“Hiwin” and helical gear racks of special precision (6th accuracy class),volume hardness28-32od on the base surface.

This processing method ensures perfect parallelism and, after collection, does not require further regulation of the operation process.

The mechanism of the portal transfers the saving of the perpendicular of the heavy-duty and rail tracks for the rigidity of the structure, which is provided by the beam to the portal and a light tubular truss, laid out behind the beam and the link є leader and leader of transportation.

The diagonals are adjusted during installation of the machine and do not become distorted during normal operation. The basic configuration of the machine has linear guides installed“Hiwin”.

High-quality powder coating ensures durable and reliable protection of all machine components.

Truck cable systems closed type company “ CPSensure reliable protection of electrical cables and gas hoses.

Railwayrequirements based on linear guides” Hiwin “,is supplied on rail beams, which ensures smooth movement of the machine’s drive mechanism. The rail beams have a welded structure with increased rigidity. To obtain the necessary characteristics, the sub-rake beams undergo a normalization process and are planed in the areas where linear guides and helical gear racks are installed. The rack teeth are of special precision, with a volumetric hardness of 28-32od. are prepared on a gear shaping bench. The technology of folding the rack will ensure an accumulated loss of crumbs of more than 0.1 mm over a maximum of 6000 mm.

Railwayrequirements based on linear guides” Hiwin “,is supplied on rail beams, which ensures smooth movement of the machine’s drive mechanism. The rail beams have a welded structure with increased rigidity. To obtain the necessary characteristics, the sub-rake beams undergo a normalization process and are planed in the areas where linear guides and helical gear racks are installed. The rack teeth are of special precision, with a volumetric hardness of 28-32od. are prepared on a gear shaping bench. The technology of folding the rack will ensure an accumulated loss of crumbs of more than 0.1 mm over a maximum of 6000 mm.

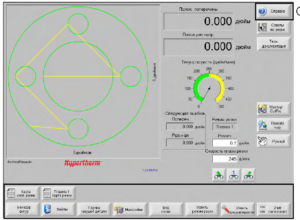

The EDGE Connect PTC system is vicorized once the HPR260XD or XPR300 plasma system is installed

Hypertherm’s EDGE® Connect numerical control system is characterized by unimproved reliability and effective implementation of functions alni possiblity and high the riven of humility of the koristuvach. This system, based on the patented Phoenix® platform for PMC, which is leading the industry, provides the operator with new software functions, including automatic opening in the ProNest® program on PMC, which implements SureCut technology ™.

Hypertherm’s EDGE® Connect numerical control system is characterized by unimproved reliability and effective implementation of functions alni possiblity and high the riven of humility of the koristuvach. This system, based on the patented Phoenix® platform for PMC, which is leading the industry, provides the operator with new software functions, including automatic opening in the ProNest® program on PMC, which implements SureCut technology ™.

The SureCut warehouse includes the following technologies:

True Hole® technologyremoves accumulations before processing, so automatically secure cutting

True Hole® technologyremoves accumulations before processing, so automatically secure cutting

To prepare the optimal configuration of the Radian® Thermal Cutting Machine under your request, please fill out this form

The scientific and manufacturing company Radian® is a distributor and manufacturer of thermal cutting machines with a revolving cycle. Our service is always carried out at the highest level at a highly professional level.

Prompt provision of spare parts is an important factor for your uninterrupted work. We maintain in our warehouse a range of blocks, assemblies, components and consumable materials necessary to maintain the efficiency of operating machines.

The established direct supply from integrated equipment guarantees minimum delivery terms.

Qualified service engineers provide technical support throughout the life cycle of the installed equipment.

Service support is provided both remotely and on-site at Koristuvachev’s premises.

Modernization of thermal cutting machines

The scientific and production company Radian® offers comprehensive services with modernization or replacement of outdated equipment for thermal cutting of any kind of plants.

Successful applications of “deep” modernization of physically and morally outdated thermal cutting machines allowed our clients to get a new product with new warranty requirements, significantly saving time and costs.