Machines of the plazma cutting "HYPERTHERM"

HYPERTHERM plasma cutting systems and original Hypertherm spare parts

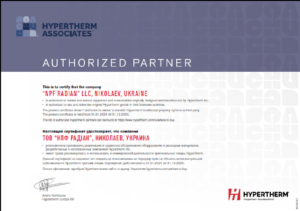

The Radian company offers a new range of Hypertherm plasma cutting systems and original spare parts and original spare parts for them.

Genuine proprietary softwareProNest (Hypertherm)

Preparing a ceramic program for a CNC machine for plasma or gas-oxide cutting of metal is a typical procedure that requires time-consuming waste. I’ll open the map – it’s no less a geometric image for a business card. Corrections for the width of the cut are made to adjust the necessary tolerances. Specks of cut holes in the sheet, soft entries into and exit from the circuit allow for the elimination of defects on the end surfaces of the machine. Directly moving along the contour in a number of drops indicates the shortness of the cut. The addition of additional sections for moving the cutting tool guarantees the absence of difficulty when bypassing the sharp edges of high-fluidity parts.

The quickest and simplest solution for preparing the chair before forming the file is to open it using a special CAD program. The finished product, prepared in the engineering department using additional CAD, is transferred to the CNC thermal cutting complex and does not require further processing or correction. With the use of high-quality licensed software products, a piece of quill is taken from the workpiece until it is physically ready.

Radian® Company offers licensed CAD/CAM software ProNest® for cutting out parts:

ProNest

ProNest LT